Cooling Tower Demonstration System

Cooling Tower Demonstration System

Figure 1: Cooling Tower Demonstration System

No

|

Component

|

1

|

Orifice

|

2

|

Water

Distributor

|

3

|

Temperature

Indicator

|

4

|

Make-up

tank

|

5

|

Heater

|

6

|

Inclined

Manometer

|

7

|

Valves

|

8

|

Receiver

Tank

|

9

|

Blower

|

10

|

Temperature

Sensor

|

INTRODUCTION

AND THEORY:

Cooling tower function is used to

cool down hot water by removing the heat. The heat of the water is mainly

removed by evaporation process. Besides that, water also cooled down by

radiation, conduction, convection. However, the effect of cooling is not

significant compared to evaporation.

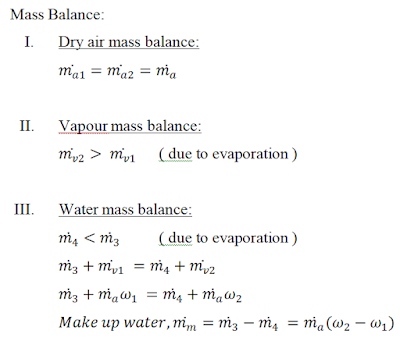

Figure 2: Schematic Diagram of Mass flow for cooling Tower

Cooling tower is widely used in industry and it main

function is removing excessive unwanted heat from high temperature water. Heat

from hot water is removed by evaporation process. However, water also cooled

down by radiation, conduction, convection. However, the effect of cooling is

not significant compared to evaporation.

In the evaporation process, small portion of water was

evaporated, thus the exiting air has higher humidity ratio and the water leave

the tower in the form of vapour. With the assumption of the dry air and water

vapour are ideal gasses, the mass of water evaporated can be determined. The

mass of water evaporated should be equal to mass of water losses in make-up

tank.

There are a few applications that are similar to the cooling

tower demonstration system such as closed-cycle wet cooling tower, closed-cycle

dry cooling tower and open-cycle cooling tower. In a closed-cycle wet cooling

system, the heat from the turbine is absorbed by a small portion of water, some

of the water released from the cooling tower as vapour and the rest being

resaved and recirculated in next cycle. The wet cooling system consumes

approximately 97% less water than the one-pass cooling system. This reduction

in the amount of water greatly reduces the number of organisms that have been

killed during ingestion.

Closed-loop circulating dry cooling tower is another

alternative that uses much less water than once through cooling, with less

environmental impact. In areas with scarce water resources, the dry cooling

system more common used because the dry cooling system required less water and

it has high energy efficiency. This system use a small amount of water and

water can be resaved and recirculated in next cycle. Therefore, the dry cooling

system solves the problem for continuous access to cooling water and does not

produce the same air quality problems as the closed-cycle wet system. The dry

cooling system also significantly reduces the volume of water discharged into

the environment, but the concentrated wastewater may contain high levels of

contaminants, which causes toxic problems. In addition, the dry cooling system

has a high capital cost and is generally less efficient than a wet cooling

system.

Open-cycle

cooling tower is removing heat from water because of the material and heat

exchange between the water and the ambient air. Warm water is pumped from the

load tank through the control valve and water flow meter to the column cap.

After water enters the tank, it is uniformly distributed over the top packing

deck and spreads over the plates. At the same time a large thin film of water

is exposed to the air stream. Then, the water is quickly cascades down the

column and leaves at the bottom. Through this process the heat exchange process

is occurred where water is cooled. However, the water cannot be cooled down

below the wet bulb temperature.

Packing Density

has linear relationship to efficiency of cooling tower. Packing Density is the

ratio of the surface areas of all levels of the cooling column to the column

volume in the units of m2 /m3. As the packing density of the distributor of

cooling tower increased, the surface area of plates that are exposed to water

increased. Total surface area and packing density of the distributor of cooling

tower can be increased by increasing the number of plates. The efficiency of

cooling tower efficiency increased as the total surface area in distributor

increased. This is due to higher evaporation rate as more water contact with

plates. Thus, more heats are removed. Furthermore, the design for arrangement of plates is important because

good design helps the water flow smoothly and the heat can be released to

environment without being trapped.

Comments

Post a Comment